Products

OEM Manufacturer Copper Wire Mesh - Woven Filter Mesh For Fine Filtration, Liquid-Solid Separation And Screening &Sieving – Anping

OEM Manufacturer Copper Wire Mesh - Woven Filter Mesh For Fine Filtration, Liquid-Solid Separation And Screening &Sieving – Anping Detail:

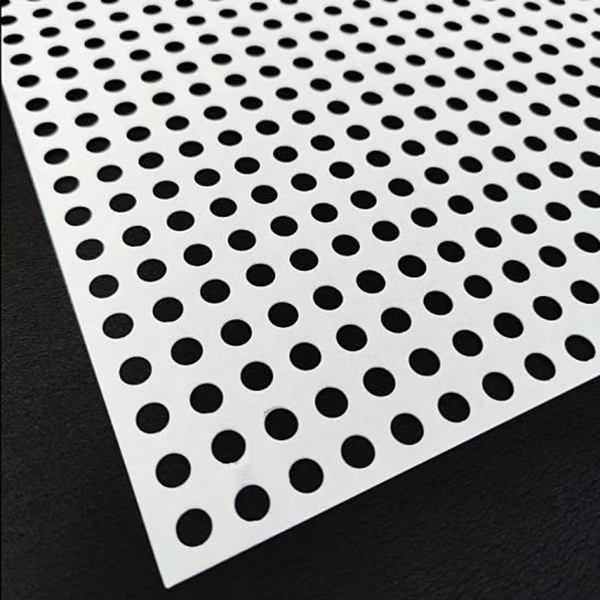

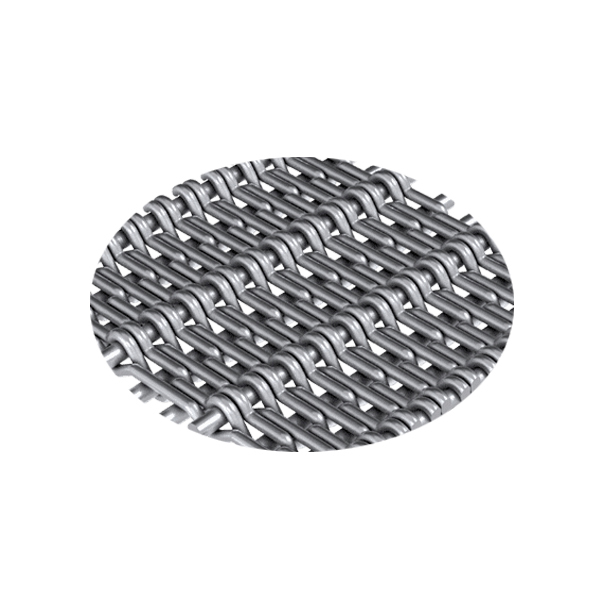

Plain Dutch Weave

This simple dutch weave is the most common filter cloth. Generally, the diameter of warp wire is larger than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is ideally suited for filtration applications, as well as the separation of slurry and liquid materials.

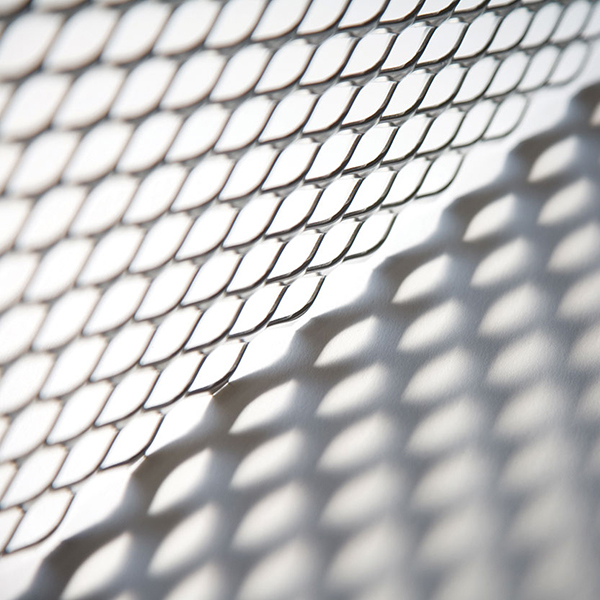

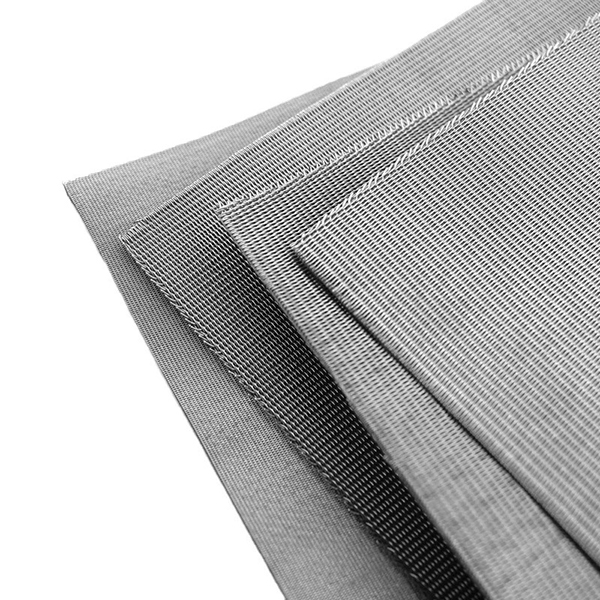

Twill Dutch Weave

This weave type offers a significant upgrade in strength over plain dutch weave wire cloth. It actually combines the Dutch and twill weaving process to produce an extremely fine mesh filtering cloth that is created by passing weft wires over and under two warp wires. As a result, it is suitable for various liquid and gas filtration applications.

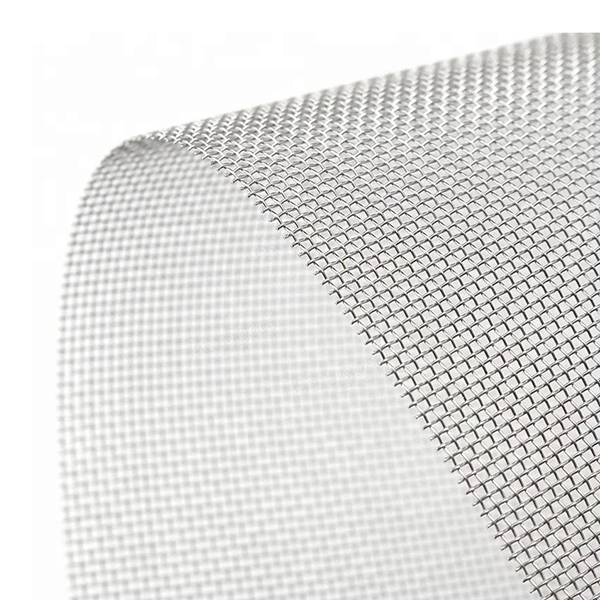

Reverse Dutch Weave

This weave type is in a reverse of the plain dutch weave wire arrangement. The diameter of warp wire is smaller than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is well-suited for high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are important.

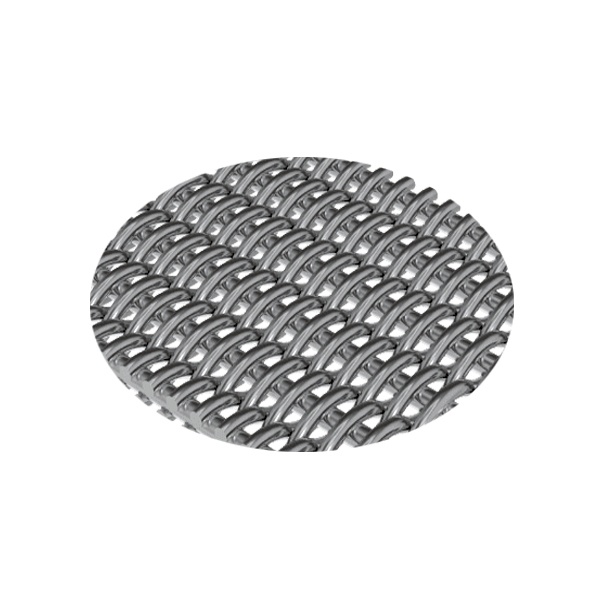

3- Heddle Twill Dutch Weave

Similar like 3-heddle weave, this type of weave has a larger diameter of warp wire than the weft wire. Besides, weft wires are closely arranged, leaving no gaps between weft wires. As a result, it is suitable for filtration applications that require high filtration accuracy and heavy load bearing capacity.

Specification

Material: stainless steel, brass, copper, nickel,iron,galvanized.

Filter rating: 2–400 μm

Woven Filter Mesh

| Mesh No. | Wire Diameter mm | Mass kg/m2 | Filter Rating μm |

| 6 × 45 | 0.10 × 0.60 | 5.3 | 400 |

| 12 × 64 | 0.60 × 0.40 | 4.2 | 200 |

| 14 × 88 | 0.50 × 0.35 | 2.1 | 150 |

| 12 × 90 | 0.45 × 0.30 | 2.6 | 135 |

| 13 × 100 | 0.45 × 0.28 | 2.58 | 125 |

| 14 × 100 | 0.40 × 0.28 | 2.5 | 120 |

| 16 × 125 | 0.35 × 0.22 | 2 | 110 |

| 22 × 150 | 0.30 × 0.18 | 2 | 100 |

| 24 × 110 | 0.35 × 0.25 | 2.65 | 80 |

| 25 × 170 | 0.25 × 0.16 | 1.45 | 70 |

| 30 × 150 | 0.23 × 0.18 | 1.6 | 65 |

| 40 × 200 | 0.18 × 0.12 | 1.3 | 55 |

| 50 × 230 | 0.18 × 0.12 | 1.23 | 50 |

| 80 × 400 | 0.12 × 0.07 | 0.7 | 35 |

| 50 × 250 | 0.14 × 0.11 | 0.9 | 40 |

| 20 × 250 | 0.25 × 0.20 | 2.8 | 100 |

| 30 × 330 | 0.25 × 0.16 | 2.55 | 80 |

| 50 × 400 | 0.20 × 0.14 | 2.14 | 70 |

| 50 × 600 | 0.14 × 0.080 | 1.3 | 45 |

| 80 × 700 | 0.11 × 0.076 | 1.21 | 25 |

| 165 × 800 | 0.07 × 0.050 | 0.7 | 15 |

| 165 × 1400 | 0.07 × 0.040 | 0.76 | 10 |

| 200 × 1400 | 0.07 × 0.040 | 0.8 | 5 |

| 325 × 2300 | 0.035 × 0.025 | 0.48 | 2 |

| 400 × 125 | 0.065 × 0.10 | 0.7 | 50 |

| 260 × 40 | 0.15 × 0.25 | 2.15 | 65 |

| 130 × 35 | 0.20 × 0.40 | 3.1 | 90 |

| 152 × 24 | 0.30 × 0.40 | 3.6 | 190 |

| 132 × 17 | 0.30 × 0.45 | 4.1 | 240 |

| 72 × 15 | 0.45 × 0.45 | 4.5 | 350 |

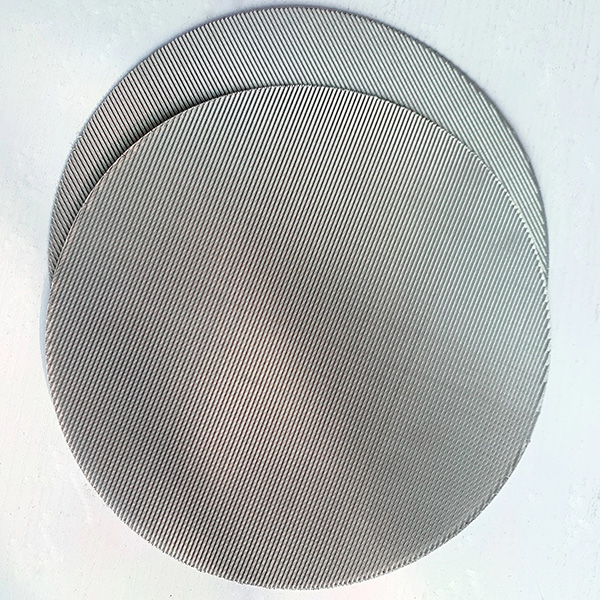

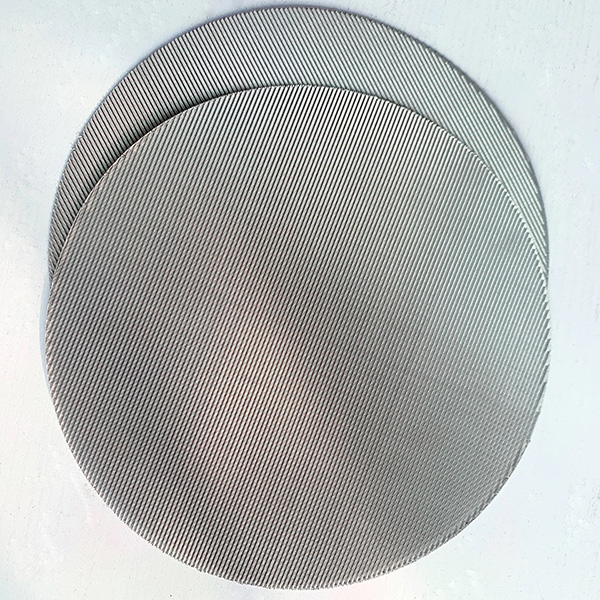

Product Display

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for OEM Manufacturer Copper Wire Mesh - Woven Filter Mesh For Fine Filtration, Liquid-Solid Separation And Screening &Sieving – Anping , The product will supply to all over the world, such as: Tunisia, Armenia, Florida, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.